Marine

Getzner has developed a group of materials in the Sylomer® Marine FR series specifically for use on ships and offshore platforms. They have been certified as fire-retardant under the IMO fire standards and SOLAS guidelines. The company also has the “wheelmark” certification required for products used on board marine vessels. BH&C Dynamics can supply Sylomer® Marine FR series to our customers.

BENEFITS FOR OUR CUSTOMERS

- Effective sound and vibration isolation

- Solutions with fire safety certificate conforming to IMO MED 307(88), FTP Codes 2 and 5 referred to in the SOLAS Convention and with Wheelmark approval

- Lower lifecycle costs

- Very good price/performance ratio

- Worldwide availability

SYLOMER AND SYLOMER MARINE PRODUCT BENEFITS

- Available with fire safety certificate in conformity with IMO MED 307(88), FTP Codes 2 and 5 referred to in the SOLAS Convention and with Wheelmark approval

- Outstanding material properties, retained over decades

- Low weight, easy handling and installation

- Excellent static to dynamic stiffness ratio

- Highly efficient with smaller thicknesses (reduction in the height of floor constructions)

- Resistant to water, salt water, oils and greases

Our marine applications are suitable for:

YACHTS

Vibration and secondary airborne noise significantly impact on the sense of well-being of those on board, to the extent of detracting from outstanding design, innovative technical features and luxurious interior fittings.

CRUISE SHIPS

IMO/SOLAS certified vibration isolation from Getzner ensures passengers enjoy their voyage in comfort: There is no sound transmission from entertainment areas or engines to the cabins.

SERVICE VESSELS

Getzner vibration isolation reduces noise levels for the crew: Standards-compliant accommodation and working conditions can be assured by decoupling the crew areas, the wheelhouse and the work platforms from the rest of the ship.

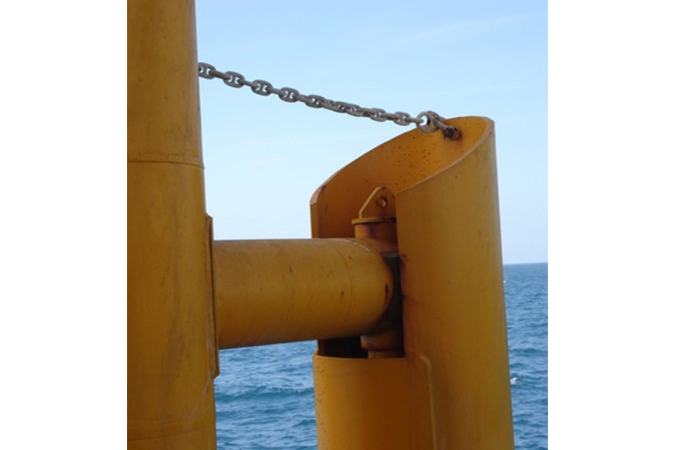

OFFSHORE PLATTFORMS

Vibration isolation from Getzner lowers lifecycle costs: Vibrations can be prevented from spreading to the structure by implementing appropriate measures. In this way, lifecycle costs can be lowered not just now but in the future.

BH&C Dynamics® and our manufacturing partners provide variety of vibration isolation materials, shock absorbers and high-tech elastomeric-damping hardware to the customer, including:

- Rubber foam filled fenders

- Rubber strip for boat-landing

- Shockcell

- Eccentric pumper ring

- Float-over hardware including Leg Mating Unit (LMU), Deck Support Unit (DSU) & Fender System